Nestled among the mountains of Mentougou District, Beijing, Liuliqu Village has nurtured the world-renowned glazed ware making craft with 700 years of unquenchable kiln fire. Known as the “Hometown of Imperial Glazed Ware”, this intangible heritage craft evolved from an official kiln in the Yuan Dynasty to an exclusive supply for the Ming-Qing imperial court. Using ganzi soil as the base and glaze as the soul, it creates colorful glazed components through double firing, adorning the red walls and glazed tiles of the Forbidden City and the Summer Palace, while embodying the Chinese architectural aesthetic pursuit of “integrating form and spirit”. For foreign travelers, exploring Liuliqu glazed ware is an excellent way to understand Chinese imperial architectural decoration and ancient firing wisdom.

The historical context of Liuliqu glazed ware making is deeply marked by royal traces. As early as the early Yuan Dynasty, the government established an official kiln “West Kiln” in Liuliqu Village, with core techniques introduced by the Zhao family, a renowned glazed ware clan from Yuci, Shanxi, initiating large-scale production. Since the Ming Dynasty, Liuliqu has become the exclusive supplier of glazed ware for the imperial court due to its high-quality ganzi soil. The kiln strictly followed the regulations of the Qing Ministry of Works for production, with clear hierarchical standards and specifications for everything from tile ends and roof beasts to screen components. During the Qianlong period of the Qing Dynasty, the craft reached its peak. The fired glazed ware not only had bright colors and hard texture but also formed an official style of “imposing from a distance and exquisite up close”, becoming an important symbol of imperial power displayed in royal buildings. The roof beasts of the Hall of Supreme Harmony in the Forbidden City and the glazed tiles of the Summer Palace all came from Liuliqu Kiln.

The glazed treasures of this period are both architectural components and the integration of craftsmanship and culture. The glazed roof beasts at both ends of the ridge of the Hall of Supreme Harmony in the Forbidden City, over three meters high, are made of Liuliqu ganzi soil, meticulously carved through dozens of processes. With a majestic dragon head shape and bright golden glaze, they not only have practical functions of waterproofing and weather resistance but also imply “warding off evil spirits”. The glazed components of the Nine-Dragon Wall in the Forbidden City use multiple glazes such as yellow, green and blue, with seamless joints and natural color transitions, shining brightly under sunlight, showing the luxury of official glazed ware. Notably, every 100 pieces of Qing Dynasty official glazed ware were marked with the craftsman’s name, a accountability mechanism that forced ultimate craftsmanship, vividly reflecting ancient ingenuity. In 2008, Liuliqu Glazed Ware Making was included in the second batch of national intangible heritage list, continuing the inheritance of the millennium-old kiln fire.

The exquisiteness of Liuliqu glazed ware lies in the ultimate pursuit of raw materials and the rigorous inheritance of ancient processes. The entire craft is completed by hand, requiring more than 20 procedures and over ten days to finish. The core lies in four links: material selection, blank making, double firing and glazing, each testing the craftsman’s skills and experience. Raw material selection is extremely rigorous, only using ganzi soil from Zihuai Mountain west of Liuliqu Village. This kaolin-rich soil has excellent fire resistance and stability. After sorting, crushing, elutriation, 5-7 days of soaking and repeated stirring, it is made into delicate, smooth and crack-resistant clay, laying the foundation for subsequent firing.

Double firing and glaze formula are the soul of the glazed ware craft. The first firing is “biscuit firing”, where the dried blank is put into the kiln and fired at 1050°C until mature, resulting in an off-white, hard and compact product. After cooling and trimming, the biscuit is glazed. The glaze is based on quartz, added with metal oxides for coloring, with strict formulas for different colors. For example, yellow glaze needs to be mixed in a fixed ratio of lead oxide, feldspar and ochre. The second firing is “glaze firing”, a low-temperature secondary firing at 980°C to ensure tight integration of glaze and biscuit. Due to uneven temperature in the kiln, craftsmen adjust the silica ratio of the glaze: “hard glaze” with higher silica for the lower part to extend melting time, and “soft glaze” with lower silica for the upper part to accelerate melting, ensuring uniform color throughout. This ancient wisdom is remarkable. In addition, the four shaping techniques of “carving, scraping, pinching and painting” require apprentices to practice for 3-5 years to master, especially “pinching”, whose precision directly determines the charm of the component.

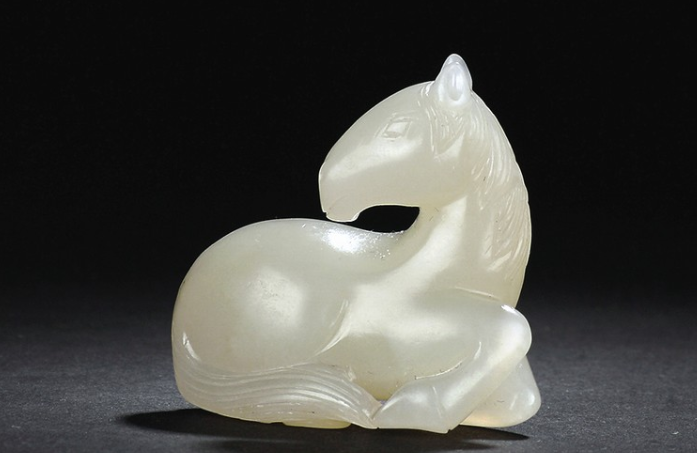

Today, the millennium-old kiln fire is revitalized under the persistence of inheritors. Jiang Jianguo, a national-level inheritor, has been engaged in the craft for nearly 50 years. Learning ancient methods since childhood, he participated in the renovation of the Forbidden City, reproducing roof beasts and other glazed components on a 1:1 scale, accurately restoring the Ming-Qing official style. The Liuli official kiln, which had been silent for ten years due to environmental protection issues, rekindled its fire in Jinyu Liuli Cultural and Creative Industrial Park in recent years. With reconstructed biscuit and glaze kilns equipped with environmental protection equipment, it continues ancient methods through green production. Inheritors not only adhere to the traditional “oral teaching and heart-to-heart transmission” but also integrate the craft into modern life through cultural and creative development and skill exhibitions, from miniature roof beast ornaments to decorative pendants, bringing royal craftsmanship into ordinary families. The younger generation learns through practice, guarding this millennium-old craft in cultural relic reproduction and innovative design.

To experience the charm of Liuliqu glazed ware immersively, core venues are not to be missed. The Palace Museum is the first choice to appreciate finished products. The roof beasts of the Hall of Supreme Harmony, the Nine-Dragon Wall and the glazed components on palace roofs allow you to intuitively feel the peak level of official glazed ware. Jinyu Liuli Cultural and Creative Industrial Park in Liuliqu Village offers close-up visits to reconstructed official kilns, witnessing the whole process of biscuit firing and glazing. Some experience projects let visitors try simple shaping by hand. In addition, the Beijing Arts and Crafts Museum displays rare glazed ware from past dynasties, from Yuan Dynasty fragments to Qing Dynasty roof beasts, allowing you to systematically understand the evolution of the craft. Wandering in Liuliqu Village, ancient kiln sites and modern workshops complement each other, as if you can hear the echo of the millennium-old kiln fire.

From the initial ignition of the Yuan Dynasty official kiln to the rebirth of the contemporary cultural and creative park, from royal-exclusive architectural components to intangible heritage cultural and creative products, Liuliqu Glazed Ware Making carries not only a firing craft but also the crystallization of Chinese imperial aesthetics and ancient wisdom. Every handful of ganzi soil hides the gift of mountains and rivers, every kiln fire reflects the craftsman’s persistence, and every piece of glazed ware condenses millennium-old ingenuity. When you gaze at the bright glaze of the glazed ware, you can understand the Chinese pursuit of ultimate craftsmanship and nature, and feel the Oriental heritage hidden between the kiln fire and glaze colors.

暂无评论内容